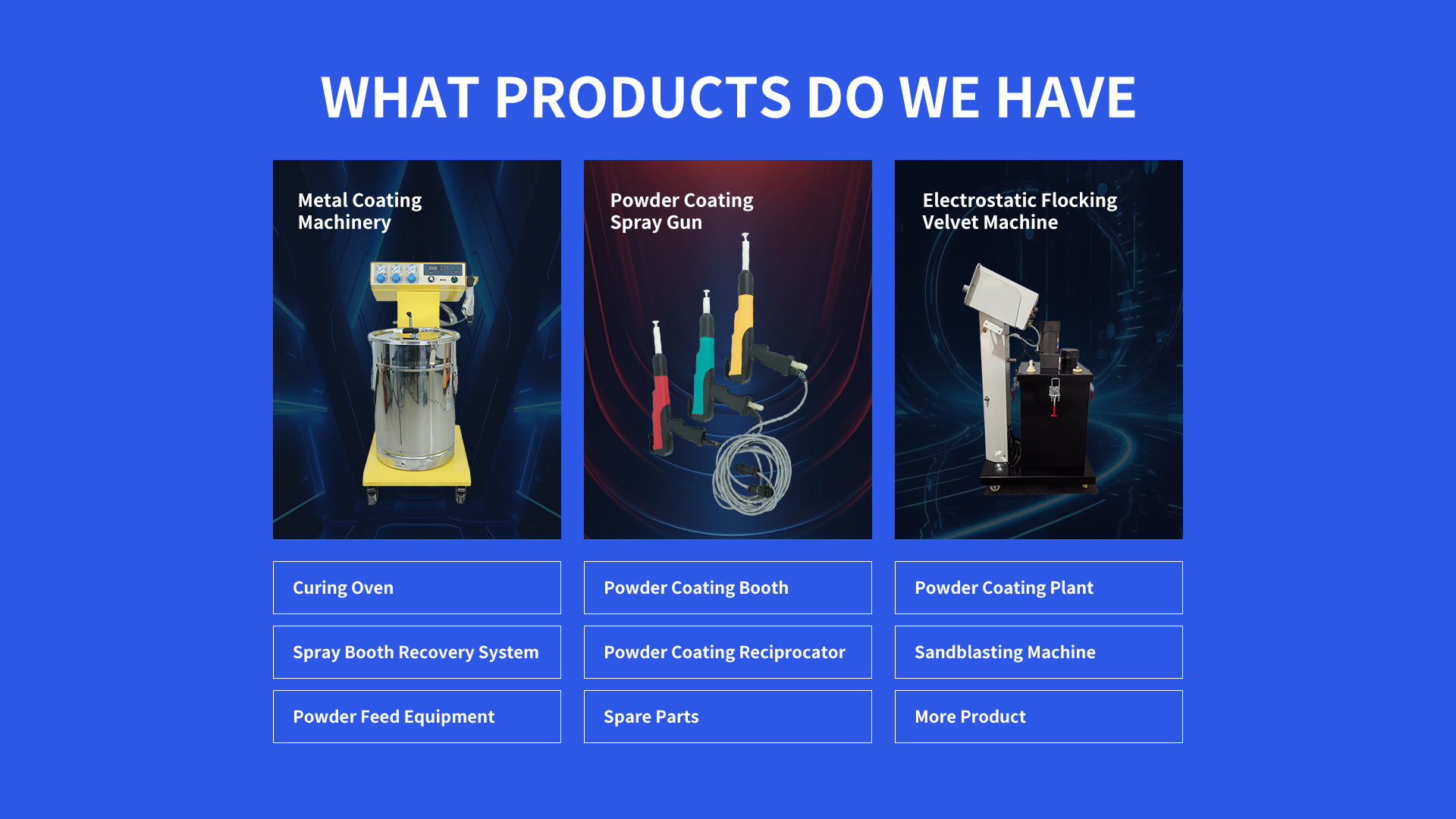

The Automatic Powder Coating Gun is a highly sophisticated piece of equipment. It features an automated powder - feeding system equipped with precise metering mechanisms, which guarantee a consistent supply of powder. An integrated electrostatic charging component is incorporated to enhance the adhesion of the powder. The gun is typically mounted on a robotic arm or an automated mechanical structure, enabling accurate and repeatable spraying operations. Additionally, there is a control panel that allows for the adjustment of key parameters such as powder - flow rate, electrostatic voltage, and spray patterns.

In large - scale automotive manufacturing, these guns are extensively used to coat car bodies and components, ensuring uniform and high - quality finishes. Appliance manufacturers rely on them to coat metal parts of refrigerators, washing machines, and other household appliances. Construction material producers utilize automatic powder coating guns to coat large - sized metal products like roofing sheets and structural steel.

Entry - level

Automatic Powder Coating Guns, suitable for small - scale industrial applications, are priced at approximately $3000 - $8000. Mid - range models, featuring better - quality components and more advanced automation functions, are priced between $8000 - $15000. High - end industrial - grade guns, designed for large - scale production lines, can cost upwards of $20000.

Before starting the operation, thoroughly check the powder - feeding system for any blockages and ensure that all connections are secure. Set the parameters according to the specific characteristics of the workpiece and the type of powder being used. During the spraying process, closely monitor the operation for any irregularities. After use, clean both the powder - feeding system and the gun to prevent powder accumulation.

Take your production volume into consideration. High - volume production requires high - end, fully - automated guns. Evaluate the types of workpieces; complex - shaped workpieces may demand guns with flexible spray patterns. Establish a budget that is in line with your long - term production plans.

Ensure proper grounding to prevent electrical accidents. Install safety guards around moving parts to avoid potential injuries. Operators are required to wear personal protective equipment, including dust masks, safety goggles, and gloves.

The automated operation ensures high - speed and consistent powder coating, significantly improving productivity. Precise control over parameters leads to high - quality finishes and reduces powder waste.

Q: What if the powder coating is too thick?

A: Adjust the powder - flow rate and spray time through the control panel. Also, check the electrostatic charge settings.

Q: Can I use different powder brands?

A: Yes, but make sure to clean the powder - feeding system thoroughly when changing powder brands to avoid contamination.

Q: How often should I maintain the robotic spraying arm?

A: Lubricate the moving parts on a monthly basis and conduct a comprehensive inspection every 3 - 6 months.

Q: What if the machine stops during operation?

A: Check the power supply and the control system for error messages. Also, look for any mechanical blockages.

Q: Can I upgrade the control system?

A: It may be possible. Consult the manufacturer regarding compatibility and available upgrade options.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com